When the valve is idle, the valve latch surface rests against the valve seat. In this way, the valve can release its heat, as the heat is transferred to the cylinder head. It is therefore important that the valve is properly connected to the valve seat. If a valve seat is worn out or no longer fits properly, the valve cannot release its heat and it does not close properly. In addition to heat conduction, this also results in the cylinder not being able to close properly, which means that the mixture/exhaust gas is lost and the compression is lower than it should be.

Valve seats often break over time because they are worn or torn. This can be due to thermal stress when, for example, the engine has often been hot, or has sudden temperature fluctuations, or there is compression of the valves in the event of incorrect valve clearance.

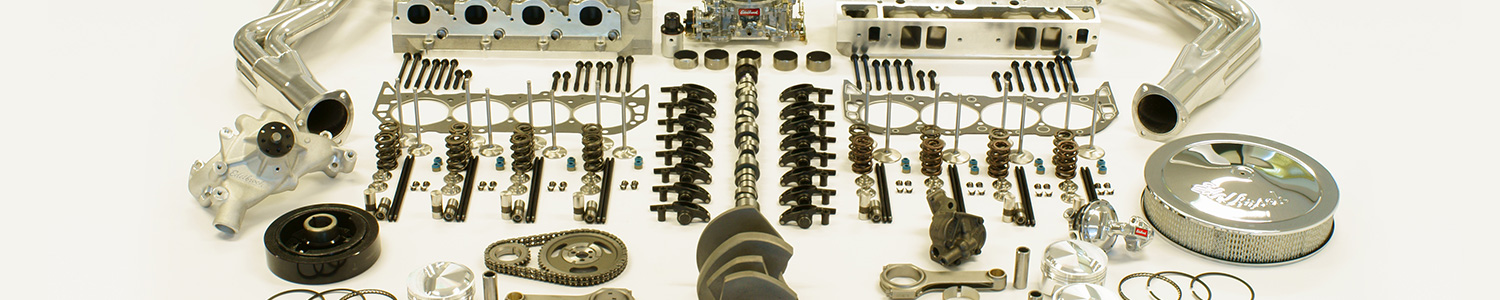

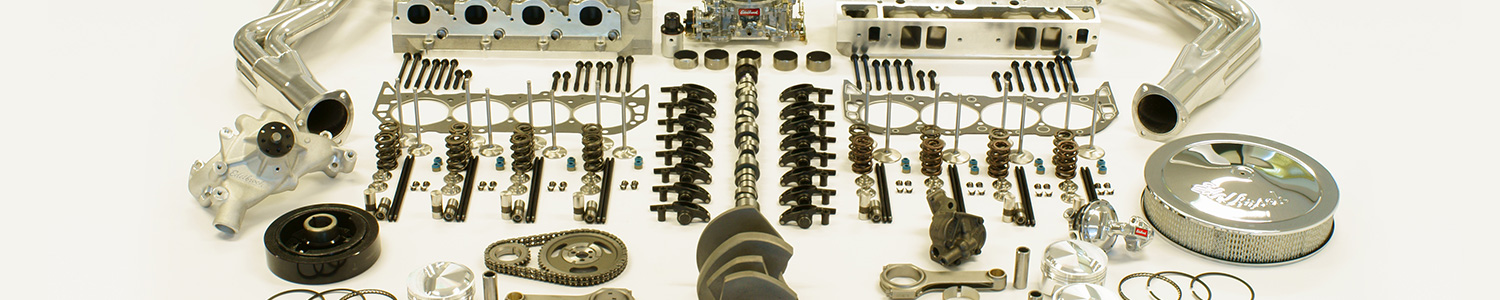

Wilmink Engine Parts offers a variety of valve seats. For example, there are hardened valve seats for vehicles running on LPG/LPI. Furthermore, it is important that the correct procedure is followed when grinding out and inserting new valve seats, depending on the type of material used (aluminium or cast iron cylinder head). If you have any questions or would like advice, please contact our product specialists. They will be happy to assist you.

Contact our product specialists; they will be happy to work with you to find a solution!

Ask your question here!

Or order via our web shop.